Category Archives: 2013_Q3

Technoledge 2013-2014 quarter 3

some further development

Group 2: Maaike Kok, shape study of the form to spice it up

Variant 1. 1 seat, 60 degrees curvature as made in Rhino.

Variant 6. Very nice curvature, attractive.

Variant 7. Model made as 3D example of a concept made by Luuk. To look if shape can stand on its own. This is possible if the back rest has enough curvature and when there is enough weight onder the seating area to keep the chair in balance.

Group 2; Variants Maaike Kok

Divided dome into three equal parts. So only the molds for one part are needed. Parts can be positioned in dome shape, but are not connected in the middle so they can be randomly scattered on a square as well if there is not enough space. Next to that this provides easy assembly since one of the three parts can be produced in one day. The next day this part can already be assembled, while the next part is being made.

Variant 1: Dome with two stairs, 90 degrees curvature. 23m2. Too big

Variant 2: Dome with two stairs, 60 degrees curvature. 17m2.

Variant 3: Dome with two stairs, 60 degrees curvature. 17m2.

Variant 4: Dome with two stairs, 60 degrees curvature. 15m2.

Variant 5: Dome with one stairs, 90 degrees curvature. 19,2m2.

Variant 5: Different parts place randomly on a square instead of in a dome shape.

Jelmer Group 2 Further developments design

Today we from group 2 continued on further developing our design. For this we took our final design from last week and the comments on it.

The most important was to make sure the design would fit into the molds. Therefore we decided that we make our design so we could use our mold three times. (The design below now has a surface of 19 m² per part, so it should fit in the available molds/mold space.)

After defining the main shape and separation of the parts we individually made some variants, below you can see mine.

Tomorrow we will further discuss them and hopefully pick one to refine.

Two variants, one very smooth and another one with some curves on the surface which makes it look more interesting (sadly it looks pretty weird on the render, I should probably change the used curves a bit to fix this.)

Different variants of the separate part (from very smooth to a curved/non smooth surface.)

Group 1 _ Niki, Elia, John, Lemonia,

Hey!

We have changed the design but we kept working on the same principle of repetition of one unit. So we can produce a variety of forms.

The compositions are produced by a translation of the unit on x and z axes and simultaneously the unit is rotating around its self on x and z axes. Then different frozen forms can be created. The form is self supported by utilizing the properties of material and the stacking method.

The forms produce both shaded and sitting space.

We continue working on the forms to solve the problem of overlapping and find the suitable intersection points to create the joints between units.

Group 4 – Reference fiberglass structures

Fiberglass connection reference projects

Serpentine Sackler Gallery – Zaha Hadid

http://www.arcspace.com/features/zaha-hadid-architects/serpentine-sackler-gallery/

Stedelijk Museum Amsterdam

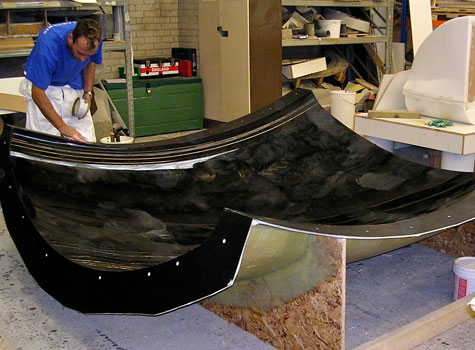

assembly

source http://www.hollandcomposites.nl/

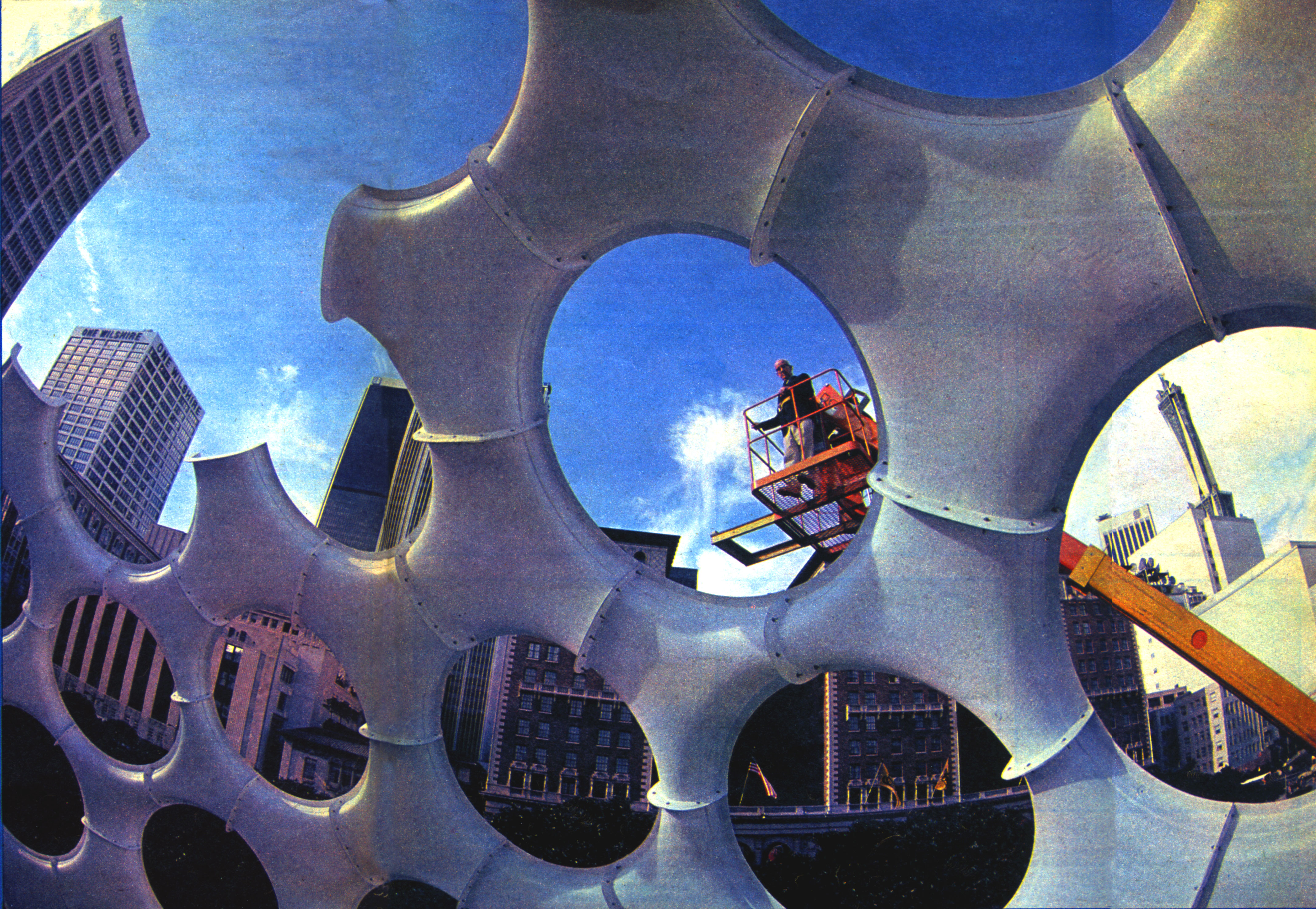

play areas for Fort Dunlop building

Eye Dome Light fesitival 2014 Amsterdam

Random

Group 3 update

We improved our model. In this new update, there are two arches in the design which each of them consist of two similar parts. Then, there are four parts in the design that can be made by the same mold. It decrease mold area to 17.3 m2.

Also, we decide to use lamination method to assembling the model because it seems to be the only way to keep the shape edges. After laminating, the edge of the composite needs to be sanded and painted to create a nice looking finishing.