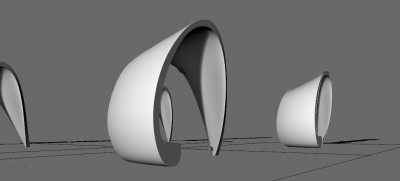

Four sand holes are placed to the inner surface of the design. Two holes for filling sand which are located on the higher part of the surface, while the rest are the holes to let the sand out, located at the seat and at the end of the leg.

We try to make it simple as possible (we are quite late for the final design). We think that the holes are needed to be insert in to the mold, while the opening caps can be done separately.

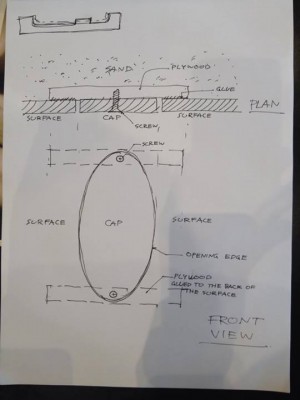

We made two connection possible details for the caps which we think that they should be able to taken off and to placed back in.

In this detail, two pieces of plywood will be glued to the back of the surface. The cap will be placed inside the opening and fixed to the plywood with screws. The problem is the screws will damage the wood after using it couple of time. Which bring us to the second detail.

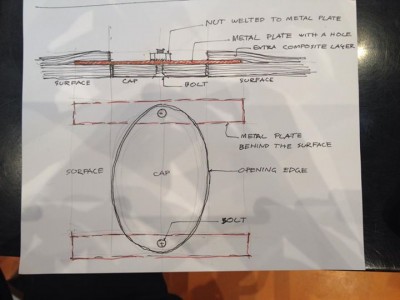

We change plywood into metal plates. The plate is needed to be drilled with a hole for let a bolt in, also a nut that is welted to the surface. With this detail the bolts cannot damage the metal plates. However, the metal plates are needed to be fix to the inner composite surface. The solution for now is to put the metals on the inner surface during hand lay-up process and apply extra layers on the top of the metals which will fix them into their places.

We still hope that someone might have the better idea than this. Something that is not too complicate and no visible screw or bolt head on the surface.

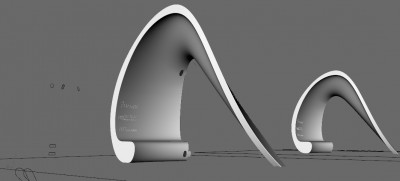

By the way, the new Polkima’s logo is applied to the design.